GX-F ADVANCED Series

With the latest in artificial intelligence (AI) and assist-gas technologies, the Mitsubishi GX-F ADVANCED Series of two-dimensional fiber lasers delivers more power while using less nitrogen and requiring less operator intervention.

AI/AR Technologies

Intuitive AI technology makes the GX-F ADVANCED Series easy to use for operators of all skill levels—especially valuable because of the ongoing shortage of skilled manufacturing workers. The machine’s augmented reality (AR) capabilities include drop and cut, part rotation and rectangular nesting.

To significantly reduce setup time, the Mitsubishi zoom head delivers speed and flexibility by automatically changing the beam size, shape and focal point for each material, with the ability to process plates with a wide range of thicknesses. Piercing time is reduced by as much as 60 percent, making it possible to pierce a 25-mm-thick mild steel within 0.8 seconds.

Mitsubishi’s proprietary AI technology monitors the cutting process in real time with audio and light sensors, automatically adjusting parameters to optimize cutting performance.

The AI nozzle monitor uses a camera system to monitor nozzle life. The nozzle changer automatically replaces defective nozzles to support continuous processing.

Adjustments are made automatically if a bad cut is detected. Cutting speed is optimized in all plates, no matter the plate quality.

Dynamic focus control automatically adjusts focus position to maintain cutting stability.

Assist Gas Technologies

The GX-F ADVANCED Series includes our AGR-MIX gas- and burr-reduction nozzle technology, which improves cut quality while reducing gas consumption when cutting mild steel–without the need for external blending tanks or high-pressure oxygen.

Building on Mitsubishi Laser’s assist gas reduction (AGR) nozzle technology that saw nitrogen assist gas consumption savings of up to 75 percent, the new AGR-MIX technology adds a further reduction of up to 50 percent without compromising cut quality.

By combining low-pressure air with nitrogen within Mitsubishi Laser’s proprietary AGR-MIX nozzle, the blended gas becomes adjustable to suit specific types of material.

The result is a cut that eliminates burr on mild steel and reduces costs associated with consumables.

Other Key GX-F ADVANCED Laser Features:

An advanced zoom cutting head delivers faster cuts with greater flexibility.

The intelligent M800 user interface offers a 19-inch screen plus intuitive smartphone-like controls.

Designed by Mitsubishi engineers and built with major Mitsubishi components, the GX-F ADVANCED Series is one of the only laser systems in the industry with a single source for service and support.

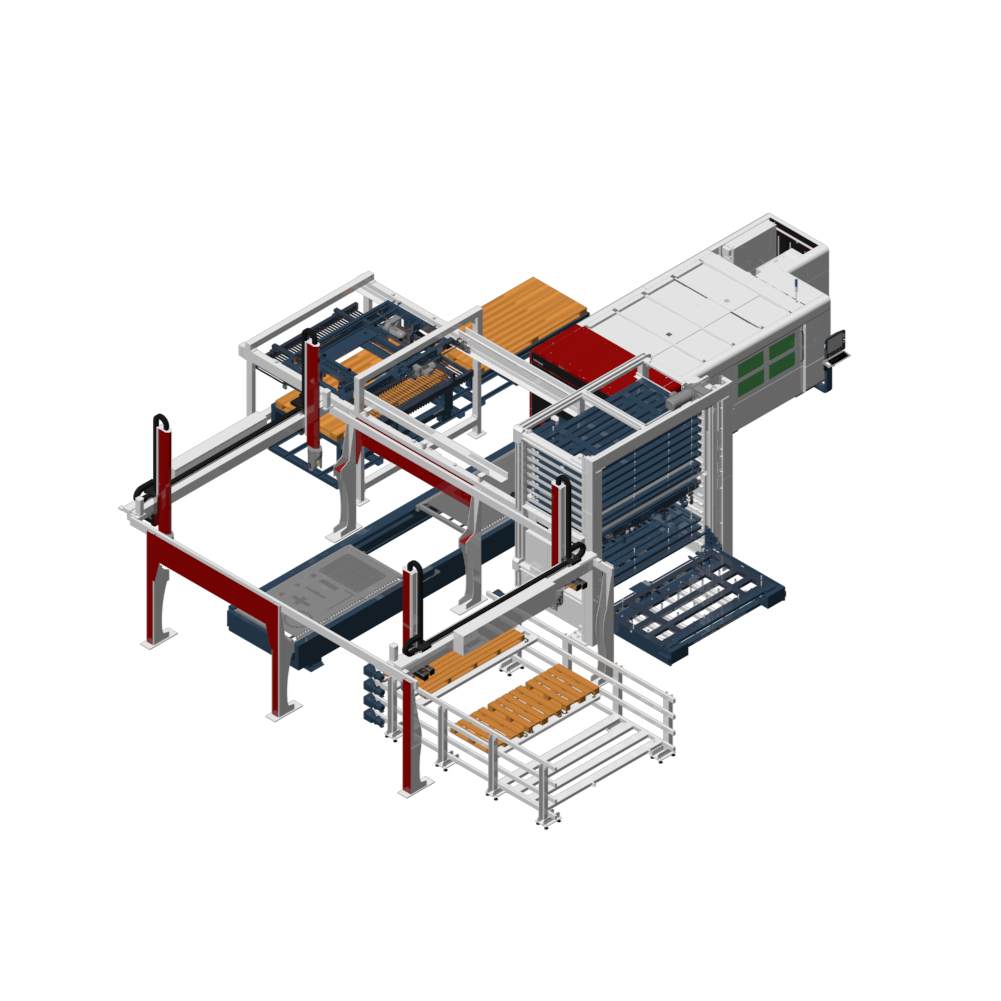

Easily integrated with modular automation and parts sorting systems, fabricators can add automation when the need arises to further reduce downtime and bottlenecks.

Robust warranties (five-year warranty on oscillator; two years on machine) plus a remote monitoring software package ensure maximum uptime.

Available in power levels from 4 kW to 20 kW.

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.